GRNN-Immune Based Strategy for Estimating and Optimizing the Vibratory Assisted Welding Parameters to Produce Quality Welded Joints

DOI:

https://doi.org/10.4186/ej.2017.21.3.251Keywords:

Welding process, mechanical vibrations, metallurgical properties, mechanical properties, plastic deformation, neural network and immune system.Abstract

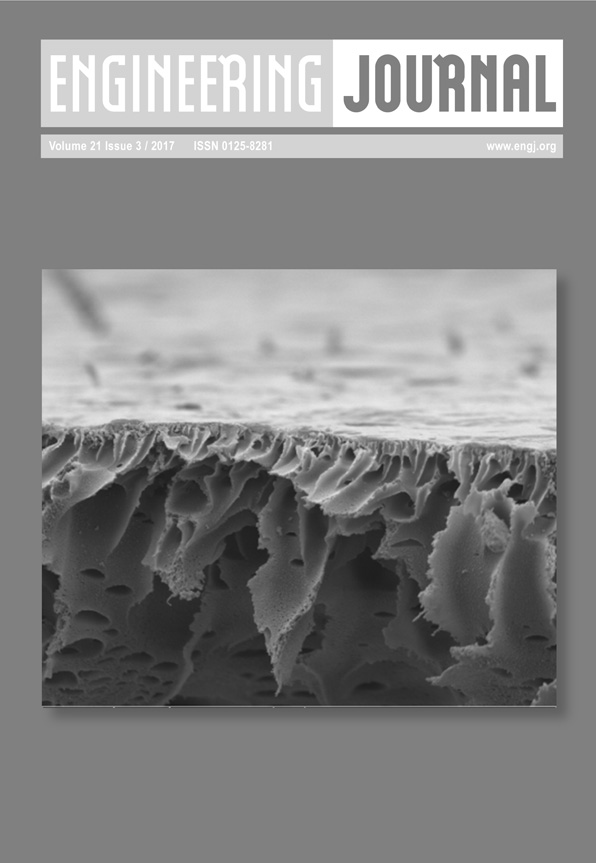

Welding is the process of producing permanent joints with the application of pressure and/or heat energy. During welding operation, weldments may be subjected to uneven thermal stresses. These stresses influence the metallurgical structure of the component. Due to this, the strength of the weld joint is reduced. Therefore, vibratory weld treatment during welding has been proposed in the present work to enhance the flexural and impact strength of weldments. However, it is found that the mechanical properties have shown nonlinear behavior with the chosen input parameters. Hence, an efficient Neural Network (NN) based prediction tool is developed to approximate the mechanical properties of weldments without performing the experiments, output values can be predicted for the given input values. Further, an immune based strategy is integrated to the developed prediction tool in order to obtain desired quality welded joints.

Downloads

Authors who publish with Engineering Journal agree to transfer all copyright rights in and to the above work to the Engineering Journal (EJ)'s Editorial Board so that EJ's Editorial Board shall have the right to publish the work for nonprofit use in any media or form. In return, authors retain: (1) all proprietary rights other than copyright; (2) re-use of all or part of the above paper in their other work; (3) right to reproduce or authorize others to reproduce the above paper for authors' personal use or for company use if the source and EJ's copyright notice is indicated, and if the reproduction is not made for the purpose of sale.